In a previous blog, we discussed the Assembly Items feature in NetSuite. But Manufacturers need more than just a parts list; they need a plan for putting those parts together. The NetSuite Work Orders feature provides that clear plan, moving you forward into production and offering a clear, trackable way to manage how and when your products are built. In this blog, we’ll walk through what work orders are and how they work in NetSuite.

Understanding NetSuite Work Orders

What Is a Work Order?

A work order in NetSuite is a record that tells your team what items to build, how many to build, and which components to use in those items. It pulls data from your assembly item and bill of materials (BOM) to give clear direction to your production process.

With work orders, you can:

- Track the status of production

- Allocate components and resources

- Monitor inventory changes

- Link to related transactions like sales orders or item fulfillments

Essentially, a work order turns your planning into action.

Why Use Work Orders?

Here are a few key reasons manufacturers lean on work orders in NetSuite:

- Inventory accuracy: With work orders, you can track the inventory of both the individual member items as well as the completed assembly items.

- Production visibility: Work orders allow you to see the whole process of creating your assembly items, from what’s in the queue, to what’s in progress, to what’s complete

- Scalability: You can start using basic work order functionality and grow into more intricate usage as your business grows, adding layers like routings and labor costing.

Types of NetSuite Work Orders

There are two types of assembly work orders in NetSuite: Special Order Work Orders and Production Work Orders.

Special Order Work Orders are typically linked to a sales order in NetSuite. With this type of work order, after you add the assembly item to a sales order, a work order will be generated if you have the member items of the assembly in stock.

Production Work Orders are not linked to a sales order in NetSuite. These work orders exist simply to regularly build up your inventory of assembly items.

Creating NetSuite Work Orders

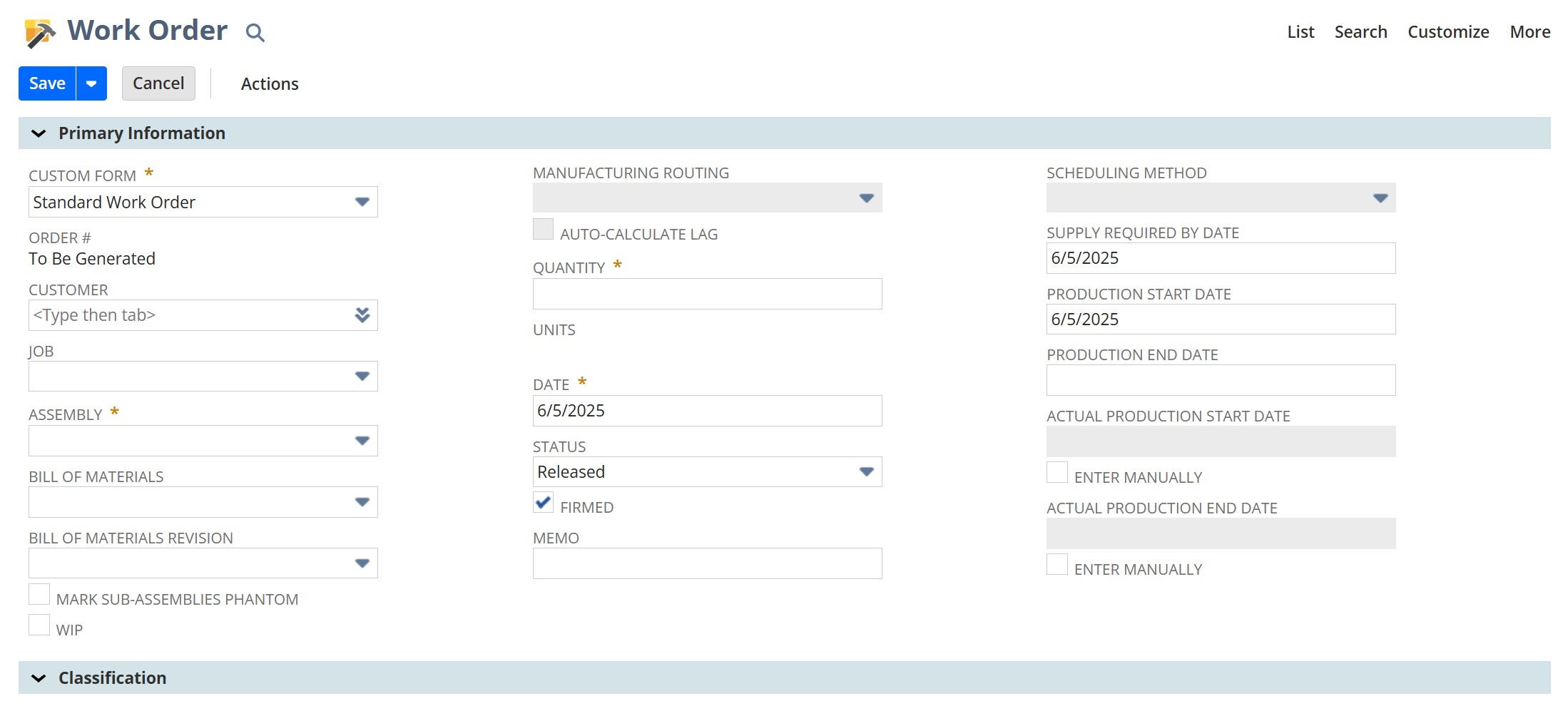

To create a work order, navigate to Transactions > Manufacturing > Enter Work Orders.

On this page, you can connect the work order to a specific customer if this is a special work order. If you’re just rebuilding stock, leave this field blank. Under the Assembly dropdown, select the assembly item this work order is for. Selecting an assembly item will cause the Items subtab to automatically populate with all the components or member items listed on the assembly item record. You can also specify the quantity of items to be created, as well as list key dates such as the date the item is needed, the production start date, and the production end date.

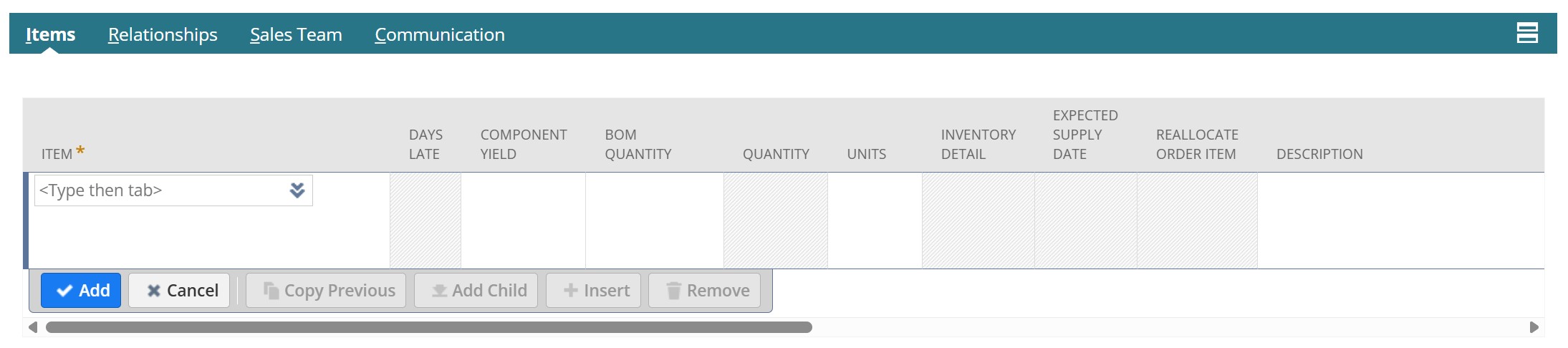

Under the Items subtab, you can review the components NetSuite pulled from the linked assembly item. NetSuite will automatically calculate the required components and provide availability information based on your inventory. If you need to add or change any items, you can do that here. When you’re finished, save the work order.

Let’s Build Smarter Together

Need help configuring work orders in your NetSuite account or wondering how to make them work better for your team? At SuiteRep, we focus on all things NetSuite—so you can focus on building better business results.

Let’s talk through your manufacturing needs. We’re ready when you are.