Managing inventory can be a constant balancing act. Companies must meet demand without overcommitting stock, especially when they have limited supply. In many businesses, orders compete for the same inventory, causing conflicts, customer dissatisfaction, and operational bottlenecks.

This is where the NetSuite Supply Allocation feature comes into play. Supply Allocation allows you to allocate available and expected inventory to specific sales and work orders in advance, so your team can control how you distribute your limited resources. By proactively assigning supply, you prioritize the most critical orders and your supply chain runs more smoothly.

What Is Supply Allocation in NetSuite?

- Supply: Inventory available for allocation, including what you have on-hand and what you will receive via purchase orders, transfer orders, and work orders.

- Demand: Transactions requiring inventory (i.e., sales orders, work orders, and transfer orders).

- Allocation Strategies: The method NetSuite uses to assign inventory.

Why Use NetSuite Supply Allocation?

- Customer Prioritization: Ensure strategic or high-value customers get supply first.

- Transparency: Sales teams can see which orders are covered and which are waiting.

- Efficiency: Prevent overpromising stock and reduce fulfillment conflicts.

- Flexibility: Align supply to demand across multiple locations and transaction types.

How Supply Allocation Works

- A sales order enters the system.

- NetSuite evaluates available and incoming supply (using on-hand, POs, transfers, WOs).

- Based on the allocation strategy, NetSuite either assigns the supply to the order or flags it for manual allocation.

Step 1: Enable Supply Allocation in NetSuite

- Navigate to Setup > Company > Enable Features.

- Under the Items & Inventory subtab, check the box for Supply Allocation.

- Save your changes.

Step 2: Create a Supply Allocation Strategy

Existing Supply Allocation Strategies

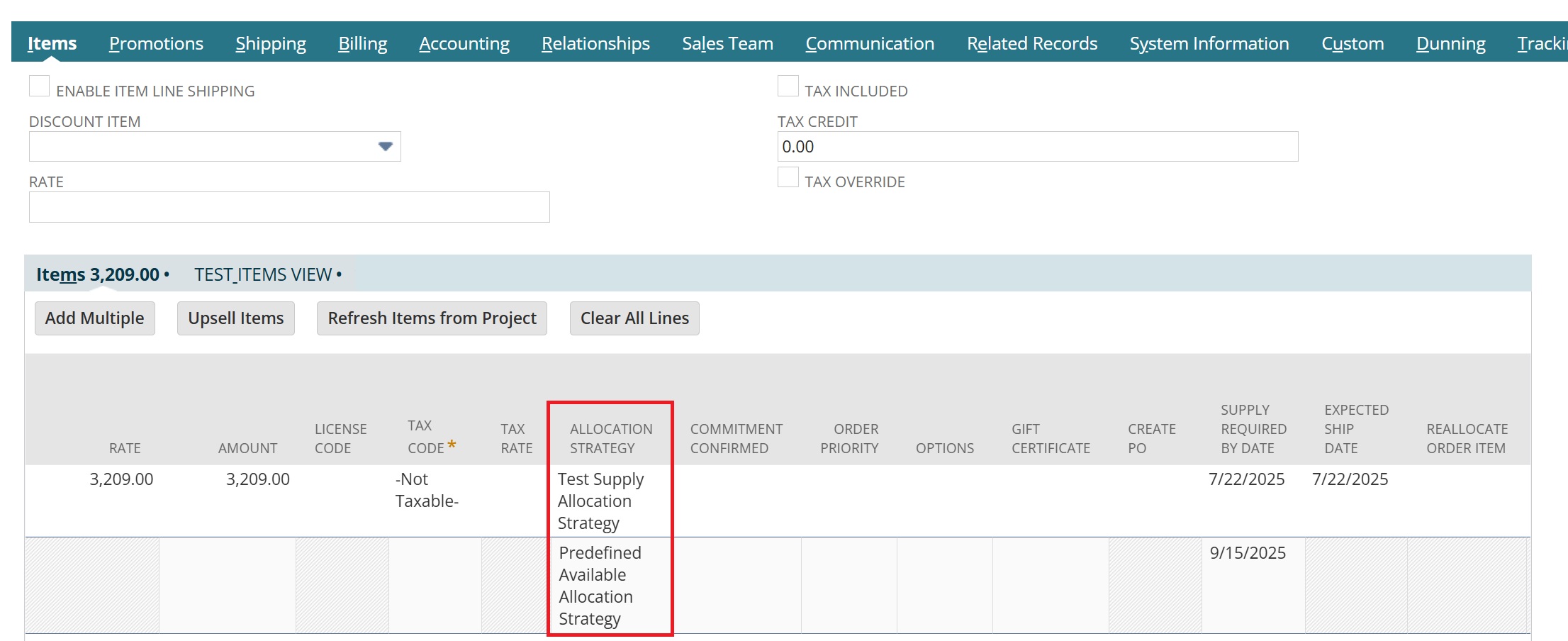

- Predefined Available Allocation Strategy: This strategy allocates inventory to orders as the inventory becomes available. This allows you to make partial fulfillments on large orders.

- Predefined Complete Allocation Strategy: This strategy requires the system to fulfill complete orders rather than partials. If you use the complete allocation strategy, large orders will not be fulfilled until the entire order is available in inventory.

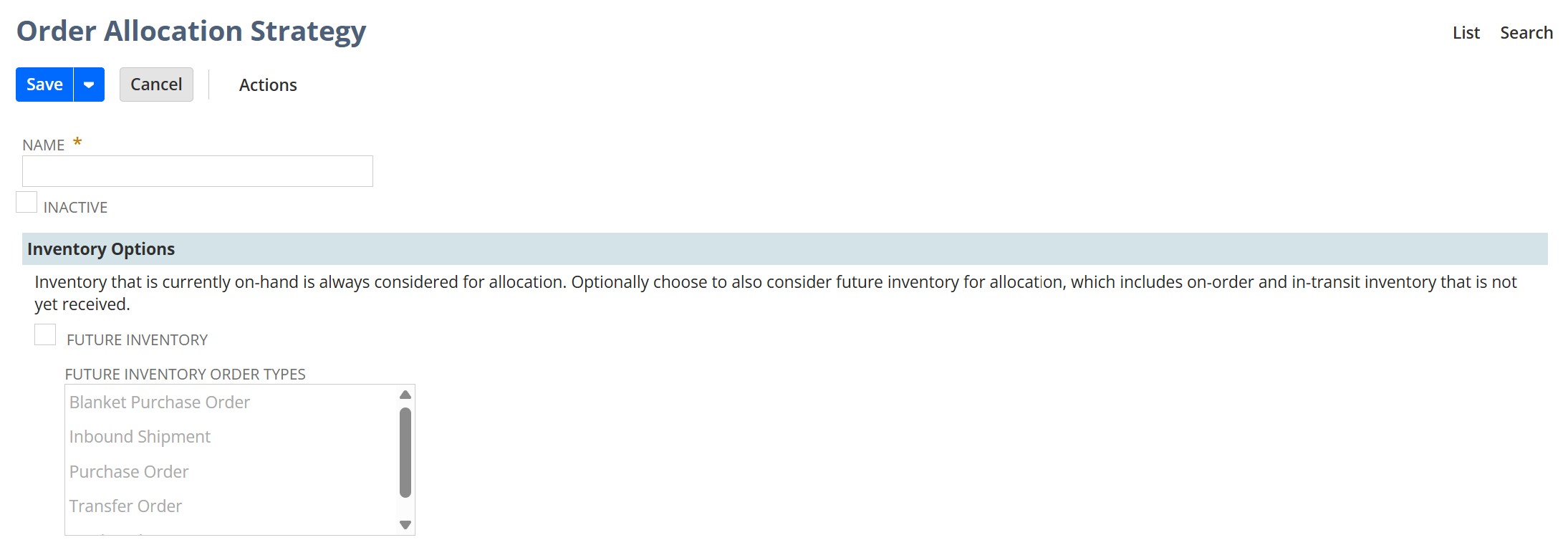

Creating New Supply Allocation Strategies

Inventory Options:

If you want NetSuite to consider future inventory in allocations, select the Future Inventory checkbox. Then, select from the list the order types you want to be included.

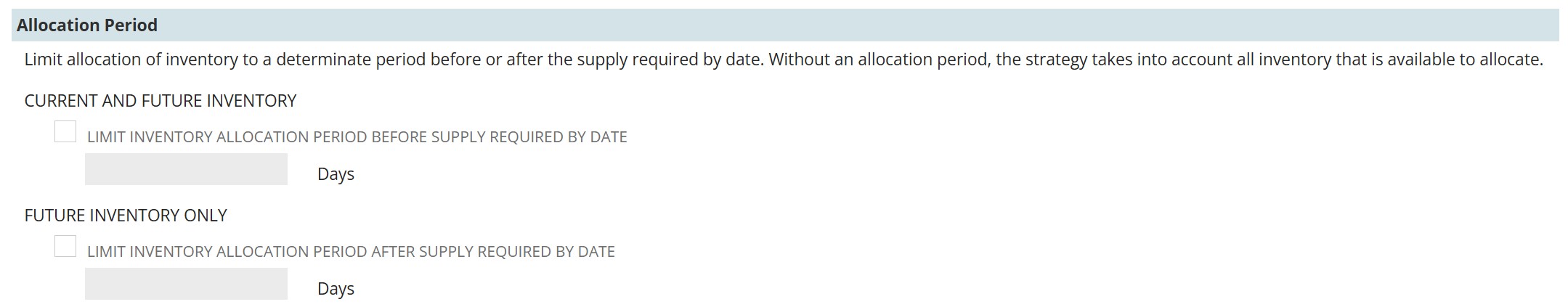

Allocation Period

Allocation Method

Allocation Quantities

Available Date Calculation

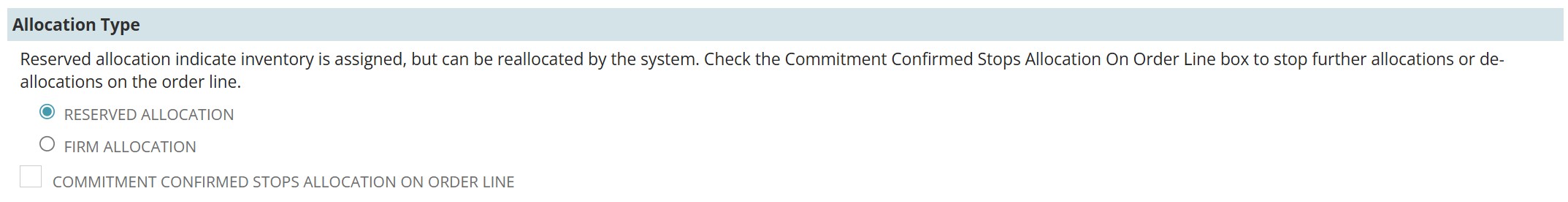

Allocation Type

Using Supply Allocation Strategies

Step 3: Create Supply Allocation Schedules

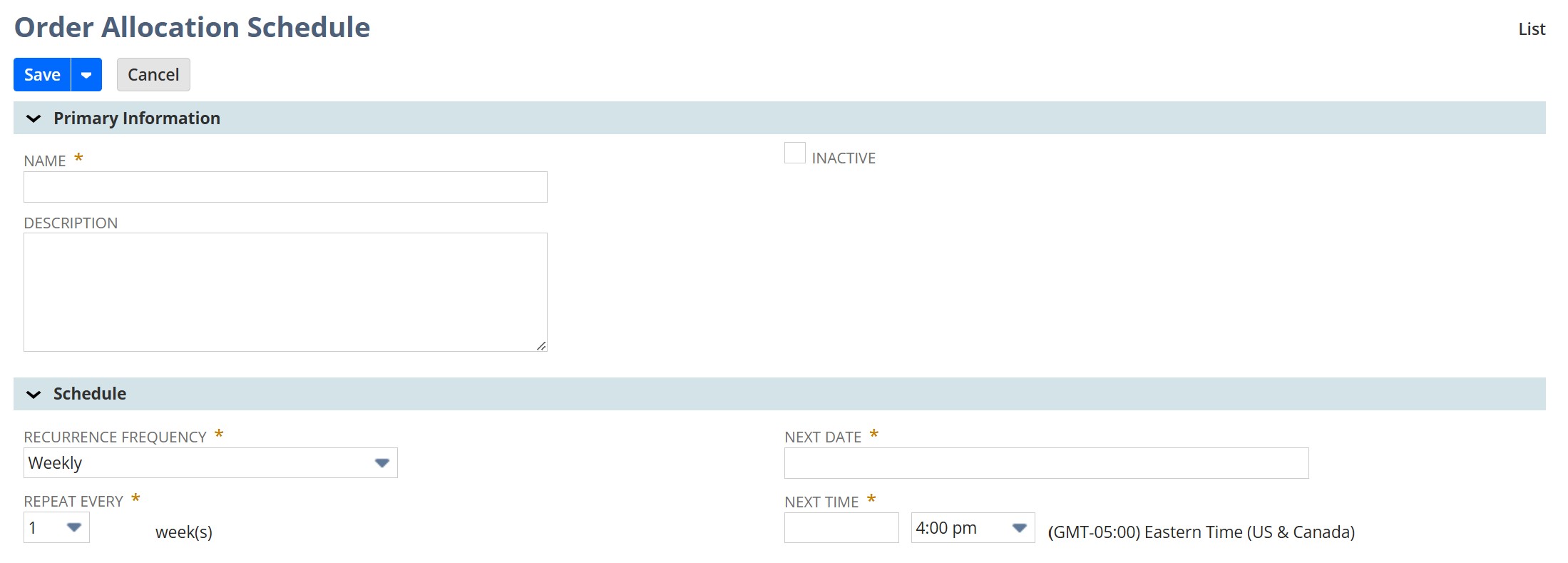

Create and Schedule

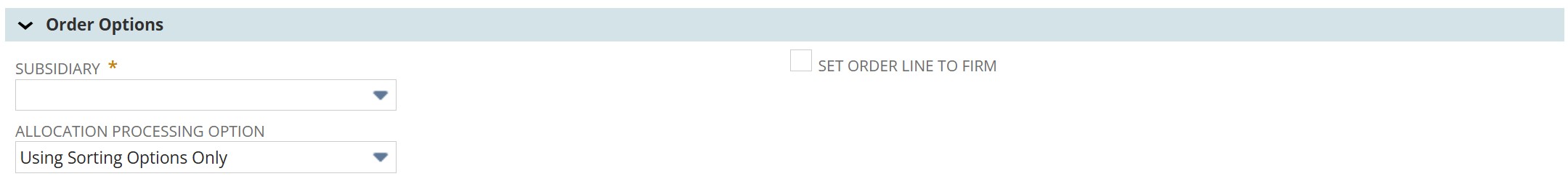

Order Options

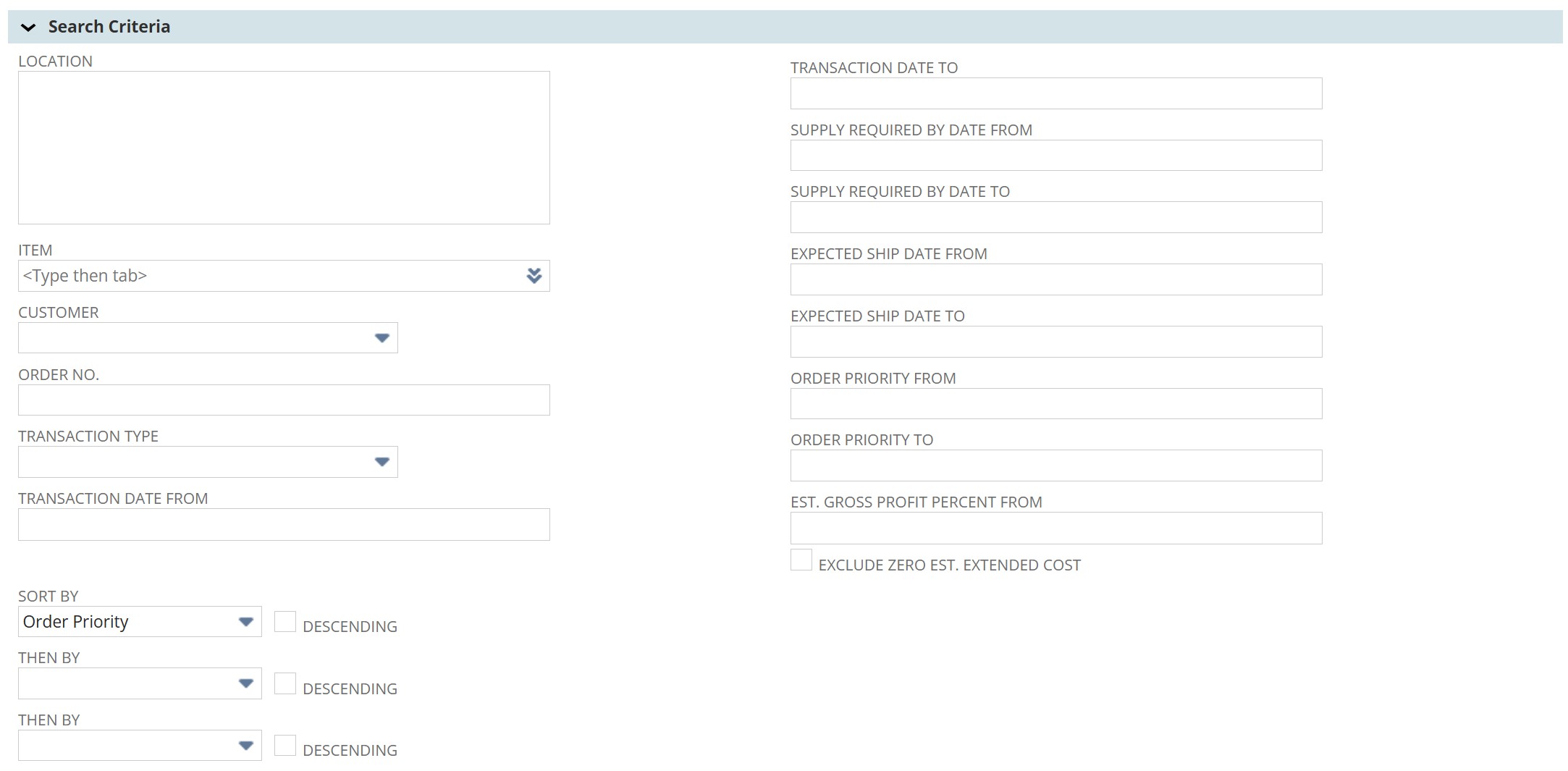

Select and Sort Orders

Search Criteria

Conclusion

If your company struggles with inventory competition between orders, it may be time to explore this feature more deeply. Reach out to SuiteRep for help configuring Supply Allocation to match your unique business rules.