NetSuite’s automation capabilities provide immeasurable value. With the NetSuite Advanced Inventory Management feature, NetSuite can automate things like calculating inventory reorder points and estimating preferred stock levels using historical and current sales data. This feature’s capabilities apply to both inventory items and assembly items. Let’s take a look at setting up and using this feature.

How does it work?

Automating inventory replenishment starts on the item record. There, you’ll need to select your inventory management preferences. NetSuite uses your preferences on the item record along with data from previous purchases and sales to project item demand and suggest item ordering. Being able to track lead time, safety stock, and seasonal demand helps you better control and optimize your inventory.

Setting it up

Enabling features

You’ll need to enable the NetSuite Advanced Inventory Management feature. You’ll find it on the Items & Inventory tab of Enable Features. This feature works in conjunction with many other inventory features, including Bar Coding and Item Labels; Lot Tracking; Matrix Items; Pick, Pack, and Ship; Serialized Inventory; and Multiple Units of Measure. When you enable Advanced Inventory Management, these features will also be automatically enabled (if they are not already in use).

Configuring item records

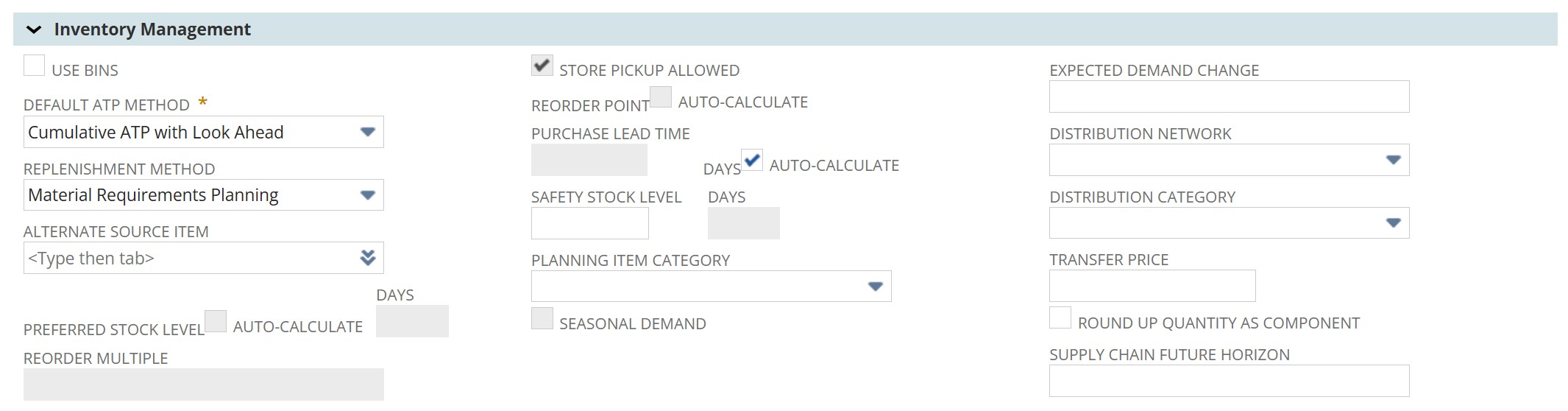

To set your inventory preferences on item records, navigate to an item record and select the Purchasing/Inventory tab. Then, scroll down to the Inventory Management section.

There are many preference options here, depending on what features and modules you have turned on. But for our purposes, the three you need to pay attention to are Preferred Stock Level, Reorder Point, and Purchase Lead Time. To employ Advanced Inventory Management on each of these, select the checkbox “auto-calculate” beside each one.

What about new items?

When NetSuite calculates things like reorder points and lead times, it’s using historical sales data. With new items, that data doesn’t exist yet. If you were to force NetSuite to make calculations, the final results would likely be inaccurate to your true needs. And so, best practice is to wait until NetSuite has an adequate amount of relevant data on an item before triggering these automated inventory calculations.

Advanced Inventory Management Calculations

Your items are set up for Advanced Inventory Management. Now what? How exactly does NetSuite make those crucial inventory stock calculations once you’ve set Preferred Stock Level, Reorder Point, and Purchase Lead Time to auto-calculate? Let’s take a look at that.

- Date of First Sale: NetSuite checks for the first sale/order of this item. This informs the system if there is enough data to process the calculation. If you also use Multi-Location Inventory, the system will measure this by location.

- Demand Per Day: NetSuite checks for demand over a set period of time. That time period will change based on whether or not you’re checking for seasonal demand. Then, the system will take the amount of orders on an item in that time period and divide that number by the days in the period.

- Auto-Calculate Lead Time: To determine lead time on an item, NetSuite will use the average lead time of the three most recent purchase orders. If you don’t have three received POs on an item, NetSuite can’t make this calculation.

- Auto-Calculate Reorder Point: NetSuite calculates this point by using daily demand for an item, estimated demand change, estimated lead time, and the safety stock amount.

Conclusion

The NetSuite Advanced Inventory Management feature provides the tools you need to ensure you stay adequately stocked on all your items across your locations. At SuiteRep, we focus on all things NetSuite so you can focus on better business results. Contact us today to start the conversation!